Motorola Drop Test Visualization

January 1st, 1999 - December 1st, 1999

Categories: Applications, Industrial VR, Tele-Immersion

About

One of the areas of research that Motorola actively engages in is the drop testing of their products. Physical drop tests typically produce few useful results as they typically only identify whether the product did or did not survive a fall. There is no easy way to observe the fall at the moment of impact. In particular there is no easy way to observe the effects of such a crash from within the device to identify key weaknesses in the product design. Computer simulation of the drop test in virtual reality, allows careful analysis of the results upon impact.

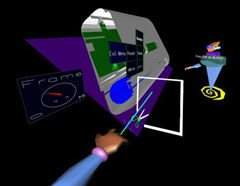

For this project the Motorola drop test of a pager is simulated on supercomputers, then the effects of the impact are reviewed from within the CAVE. Being fully immersed within the CAVE environment allows for a more natural interface to view the data. Using a cutting plane, engineers can push through the pager revealing the inner circuitry and printed-circuit board (PCB) housing. As the pager is rendered larger than life in the CAVE, the observer can physically walk inside to observe how the PCB dislodges from its housing at the moment of impact. Based on the data obtained, the designer can devise supports to further strengthen the housing.

Adding tele-immersive capabilities to this visualization tool, allows Motorola engineers to discuss and collaboratively review their findings with their colleagues around the world.